Xiamen Hengtai Forging Co., Ltd. is located in xiamen Xiangan District, Cuo Development Zone (243km from 324 National Road), the central hub of "Xiamen, Zhangzhou and Quanzhou" business circle, which is the economic leader of The West China Sea, with convenient land and water transportation.

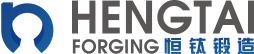

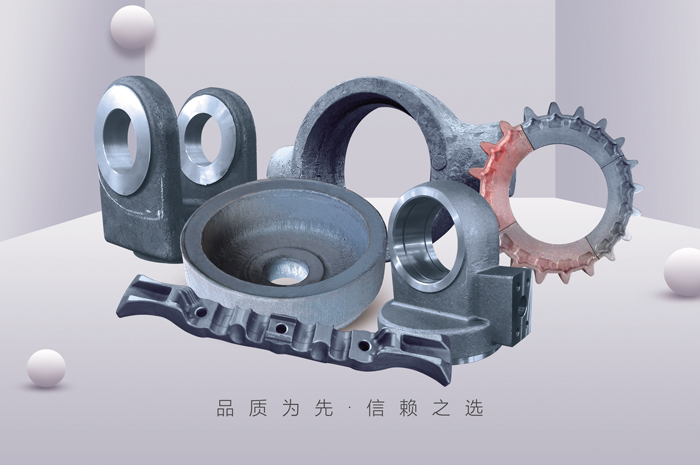

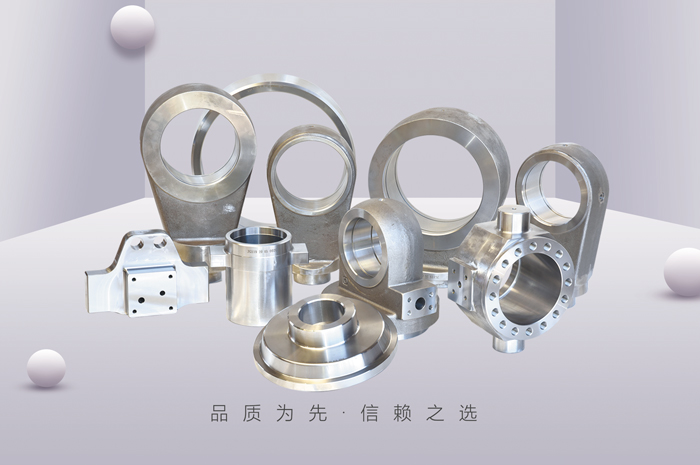

Company investment of 150 million yuan, covers an area of more than 20000 square meters, has advanced production equipment and perfect management system, including the introduction of 1000 t, 1600 t, 2500 t, 4000 t, 8000 t such as multiple advanced large press forging production line and production line and grinding ring grinding production line. And has all kinds of machining workshop, mold processing workshop, heat treatment workshop and physical and chemical testing center. At the same time, the company is also equipped with more than 100 sets of deep processing machine tools, with annual production capacity of 30,000 tons of die forging parts and 300,000 sets of excavator chassis parts.